Search

An Ounce of Prevention... The Reliability of Field Methods for Detecting the Presence of Amine Blush on Epoxy Coatings

Also Purchased

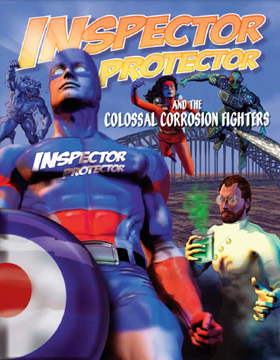

Inspector Protector and the Colossal Corrosion Fighters

Product Number:

37585

ISBN:

Inspector Protector

$2.00

Glassflake Epoxy - An excellent System for Offshore Platforms Splash Zone

Product Number:

41205-179-SG

Publication Date:

2005

$20.00

Alphatic Polyurea Speification - The Development of SSPC Paint Specification 39

Product Number:

41205-183-SG

Publication Date:

2005

$20.00