Search

Military

View as

Sort by

Display

per page

Partnering with the US Navy: Water Storage Tank Maintenance on a Global Scale

Product Number:

51219-219-SG

Publication Date:

2019

$20.00

Performing Coating And Corrosion Assessments To Maintain Military Fuel Piping

Product Number:

51322-18027-SG

Publication Date:

2022

$20.00

Polymeric Interior and Exterior Marine Decking Systems

Product Number:

41213-801-SG

Publication Date:

2013

$20.00

Single-Component Polysiloxane: An Advanced Coating for Navy and Surface Topsides

Product Number:

41215-903-SG

Publication Date:

2015

$20.00

SP0308-2018-SG, Inspection Methods for Corrosion Evaluation of Conventionally Reinforced Concrete Structures

Product Number:

21128-SG

ISBN:

1-57590-220-6

$109.00

SP0308-HD2008-SG, Inspection Methods for Corrosion Evaluation of Conventionally Reinforced Concrete Structures

Product Number:

21128-HD2008

ISBN:

1-57590-220-6

Publication Date:

2008

$179.00

SP0408-2014, Cathodic Protection of Reinforcing Steel in Buried or Submerged Concrete Structures

Product Number:

21133-SG

ISBN:

1-57590-223-0

Publication Date:

2014

$179.00

SP0408-2019, Cathodic Protection of Reinforcing Steel in Buried or Submerged Concrete Structures

Product Number:

21133-2019

ISBN:

1-57590-223-0

Publication Date:

2019

$109.00

Spot-and-Sweep' Blasting for Cost Effective Outer Hull Surface Preparation

Product Number:

41213-760-SG

Publication Date:

2013

$20.00

SSPC CPC-1/NACE SP21412-2020, Corrosion Prevention and Control Planning

Product Number:

SP21412-2020

Publication Date:

2020

$109.00

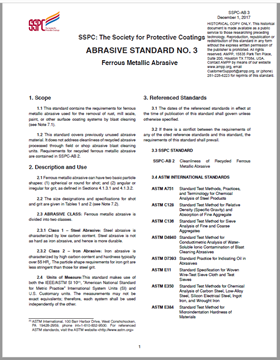

SSPC-AB 3-2017, Ferrous Metallic Abrasive

Product Number:

SSPC-AB 3-2017

Publication Date:

2017

$179.00